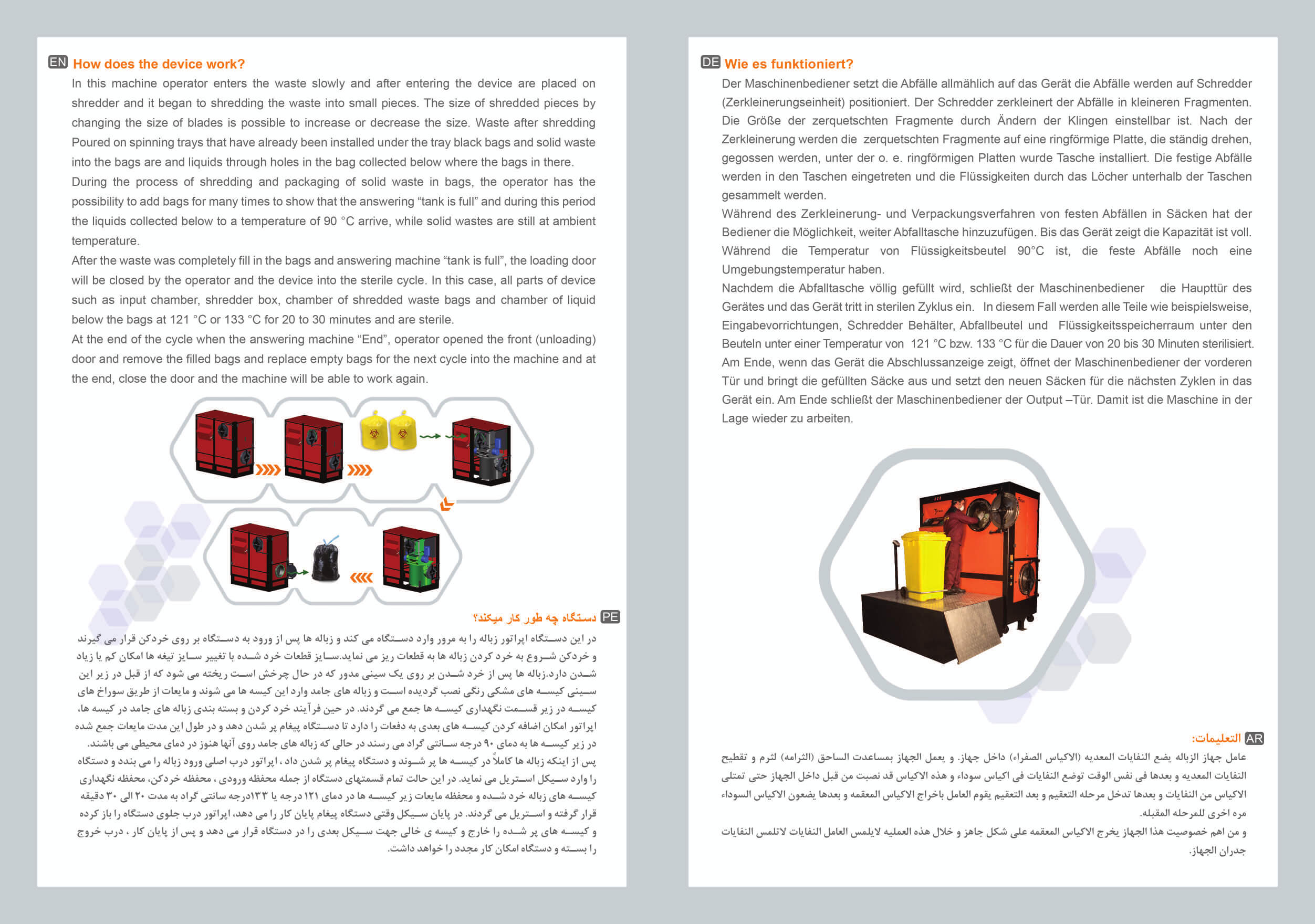

First, the operator gradually enters the waste into the machine. After entering the machine, the waste is placed on the shredder and crushed into small pieces. The size of the chopped parts can be increased or decreased by changing the size of the blades. The waste is then dumped on a rotating tray. Under this tray, black bags are installed in which solid waste enters the bags and liquids enter the lower holding part through the holes under the bag. During the process of crushing and packing solid waste in bags, the operator can add subsequent bags until the machine gives a message to fill. During this time, the liquids collected under the bags reach a temperature of 90°C while the solid waste on them is still at room temperature.

After the garbage is filled in the bags and the machine gives the message of filling, the operator closes the main door and enters the machine into the sterile cycle. In this case, all parts of the device, including the inlet chamber, shredder chamber, storage chamber for shredded garbage bags, and the liquid chamber under the bags are placed at 121°C or 133°C for 20 to 30 minutes and sterilized. At the end of the cycle, when the machine gives the message of finish, the operator opens the front door of the machine takes out the filled bags and places the empty bag for the next cycle in the machine. After finishing work, close the exit door and the device will be able to work again.

Surgery Room

Surgery Room  Medical Consumables

Medical Consumables  Medical Imaging

Medical Imaging  Cardiovascular

Cardiovascular  Infection Control

Infection Control

phone consultancy

phone consultancy

Download catalog

Download catalog