Air Quality

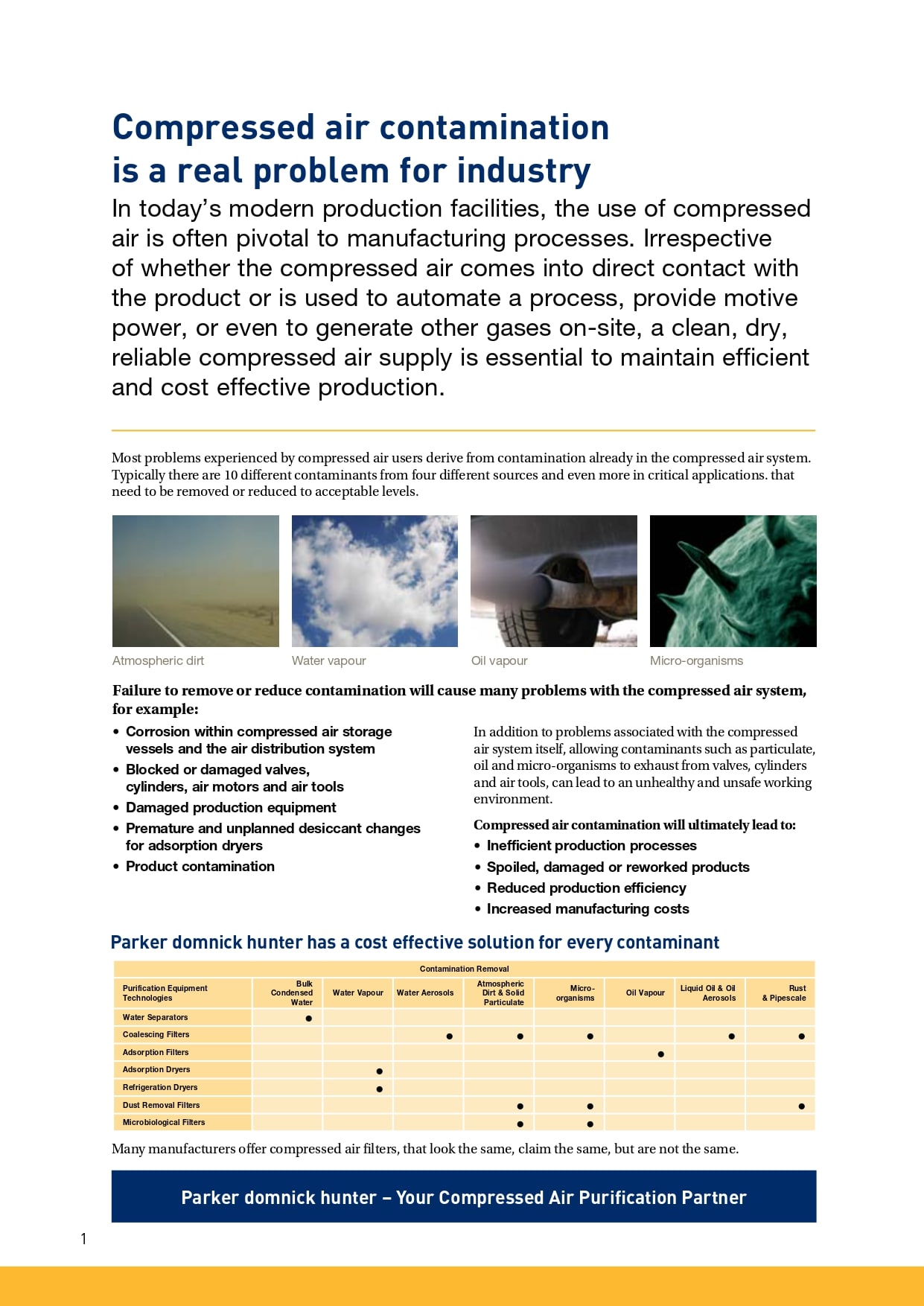

The primary reason for using a compressed air filter is to remove contamination and improve air quality. OIL-X filter not only produces the highest air quality, but it also consumes very low energy, produces the least amount of CO2, and reduces costs.

The OIL-X Evolution filter function is approved by the Lloyds Register. Also, the air quality produced by this filter complies with the quality classifications of ISO8573-1 when tested with the methods and equipment stated in ISO8573 and ISO12500. So, it is the only filter that guarantees a one-year air quality.

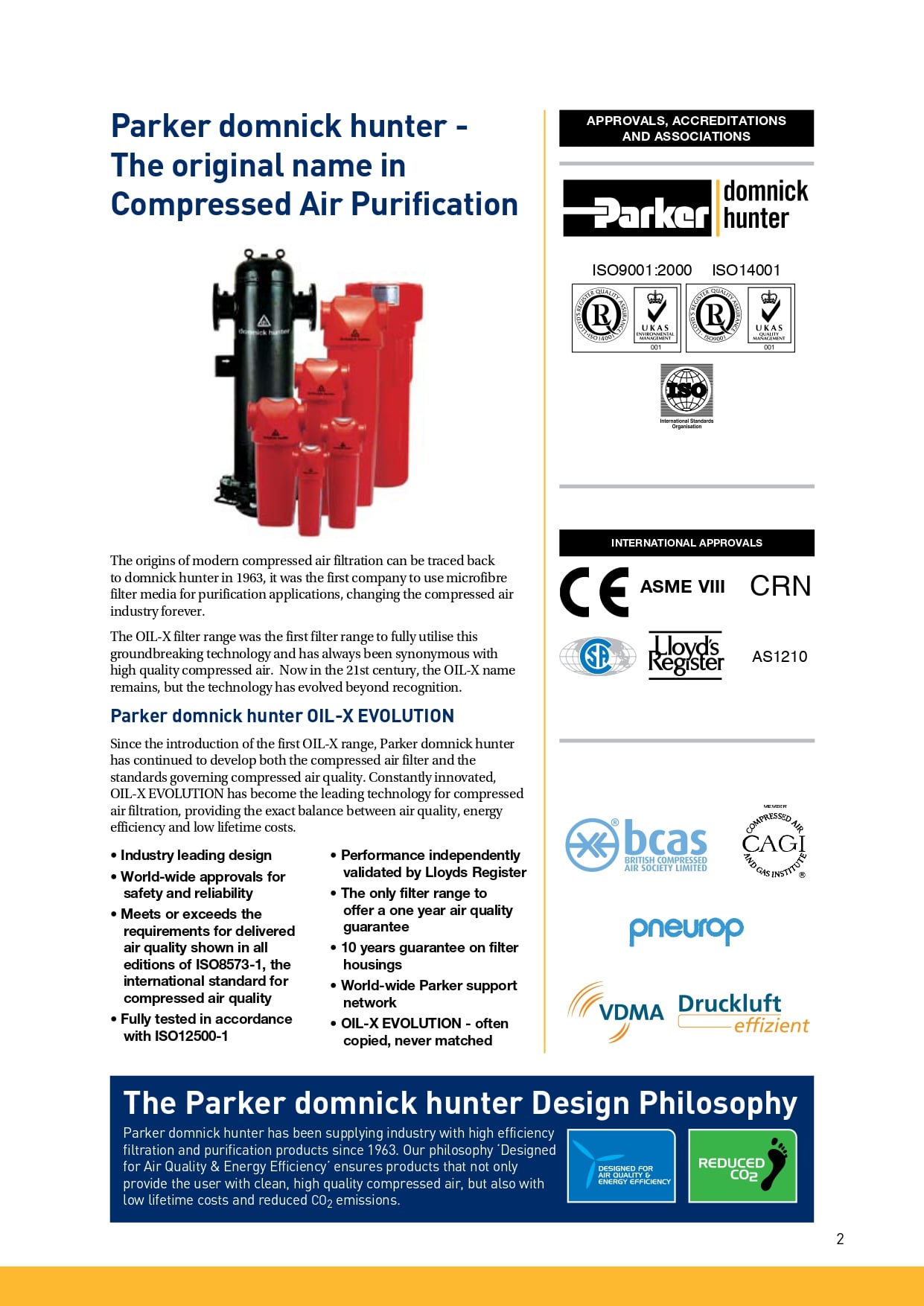

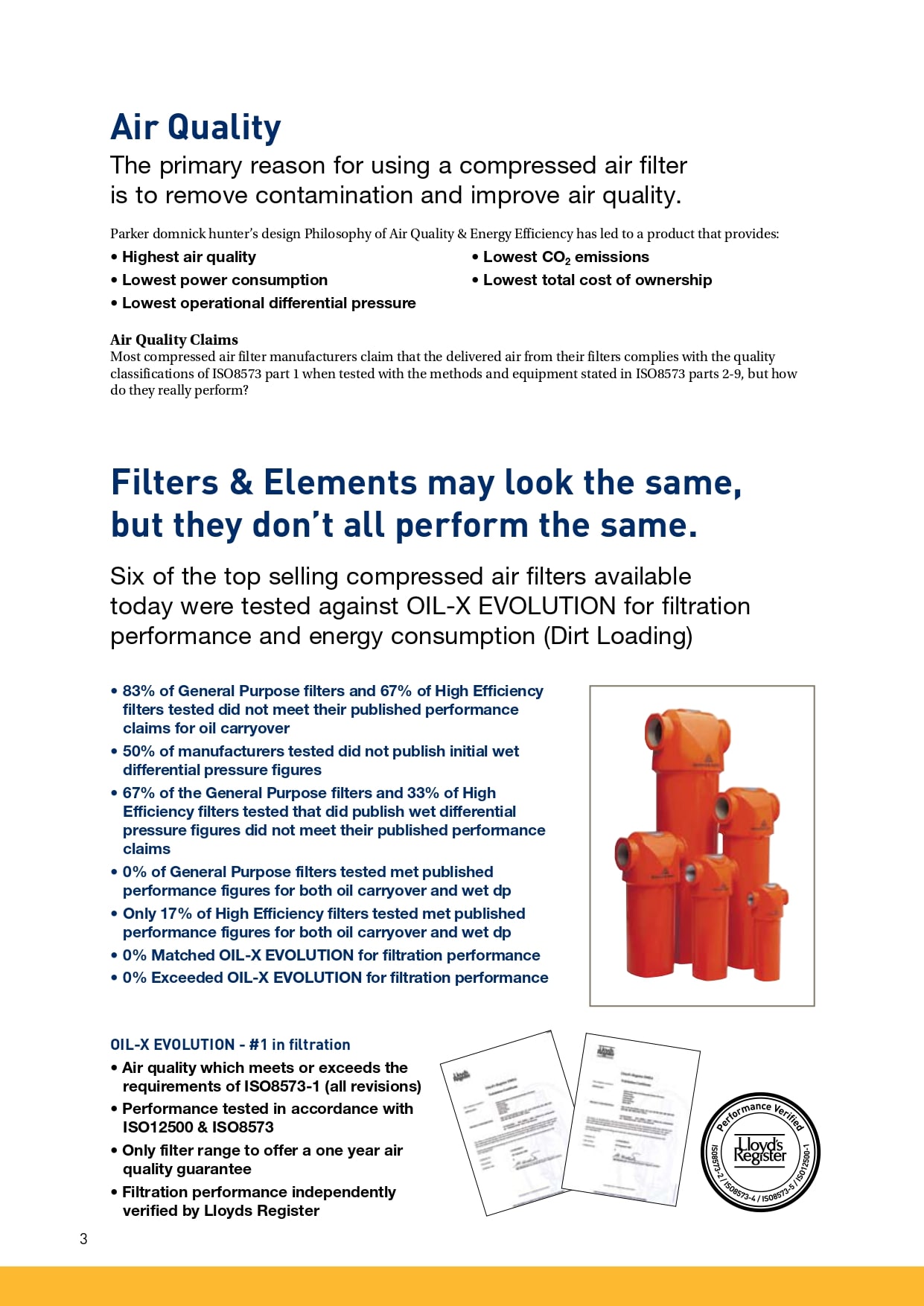

Energy Efficiency

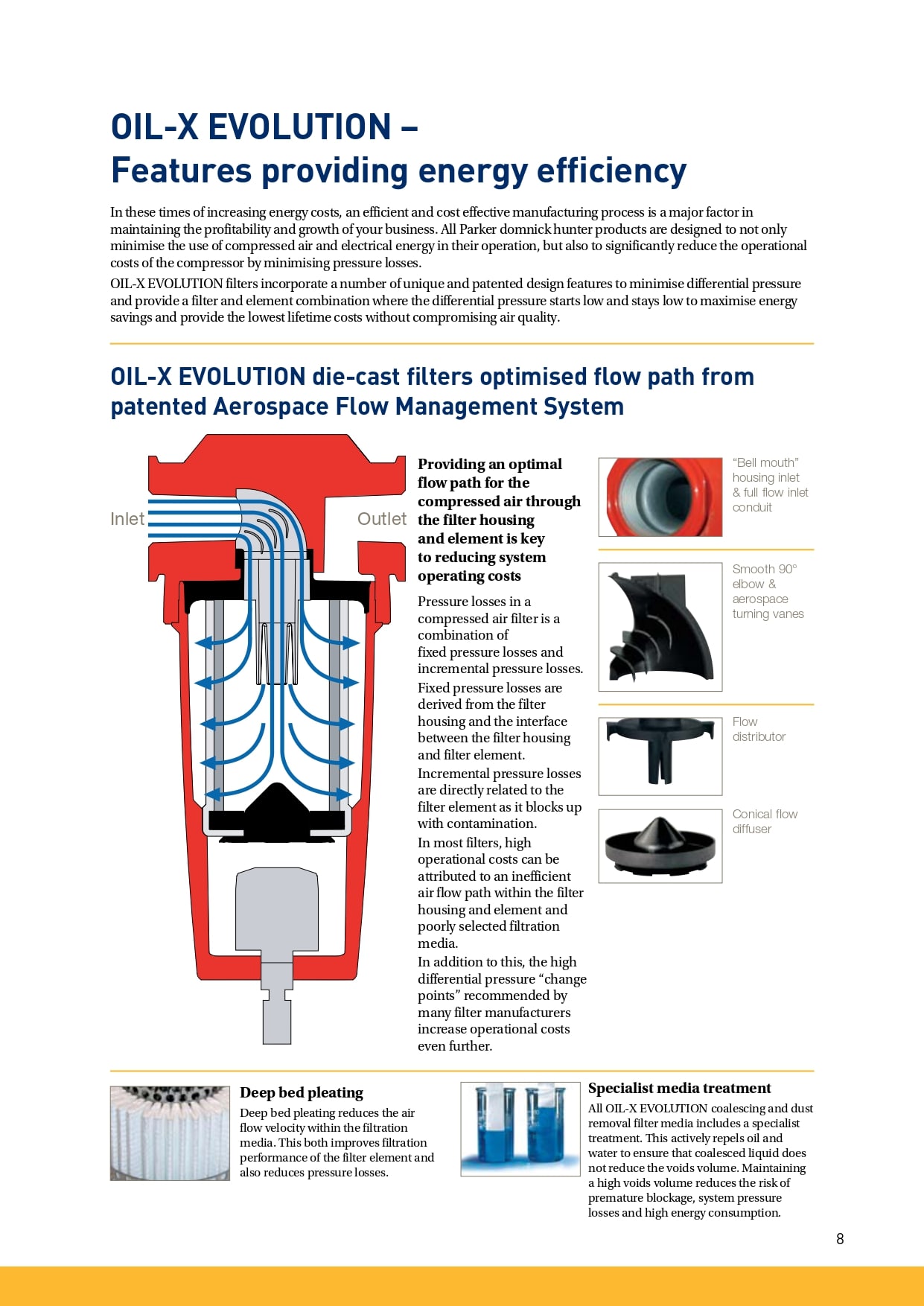

Any restriction to air flow within a filter housing and element will reduce the system pressure. To generate compressed air, large amounts of electrical energy are consumed, therefore any pressure losses within the system can be directly converted into a cost for wasted energy. The higher the pressure loss, the higher the energy cost. The OIL-X Evolution filter has a very small pressure drop compared to other filters, which significantly reduces energy consumption.

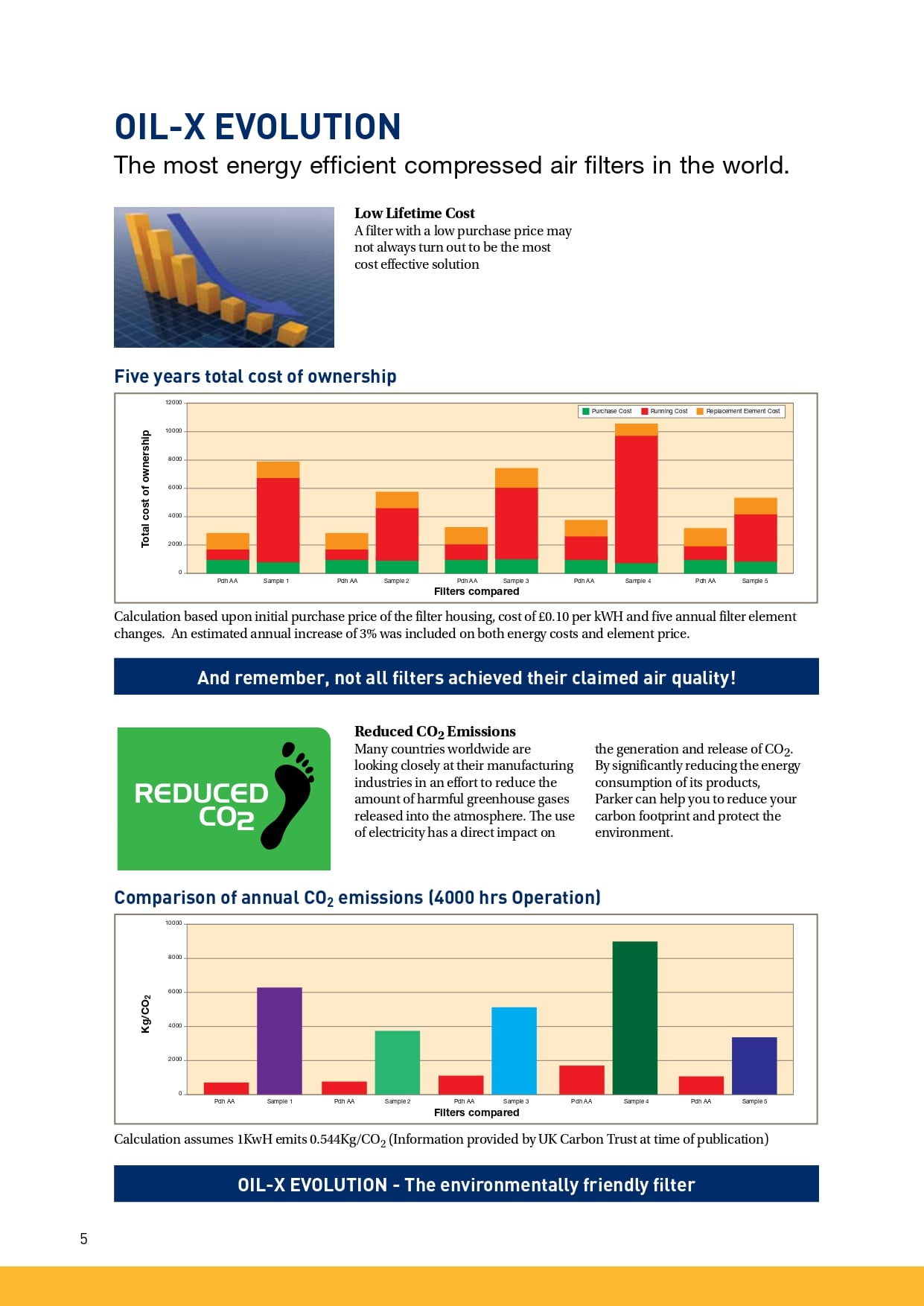

Reduced CO2 Emissions

Many countries worldwide are looking closely at their manufacturing industries to reduce the amount of harmful greenhouse gases released into the atmosphere. The use of electricity has a direct impact on the generation and release of CO2. By significantly reducing the energy consumption of OIL-X Evolution filter, Parker can help you to reduce your carbon footprint and protect the environment.

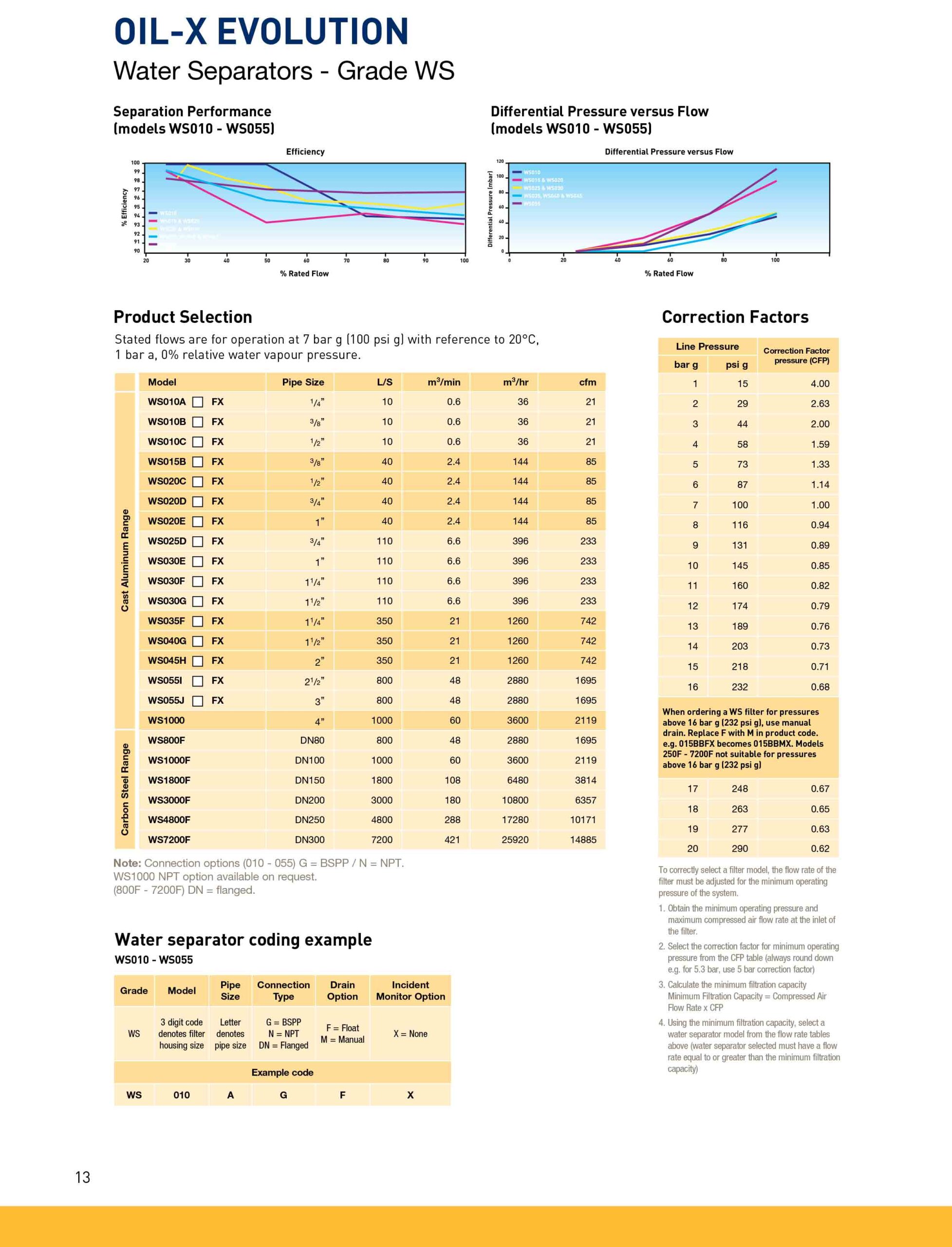

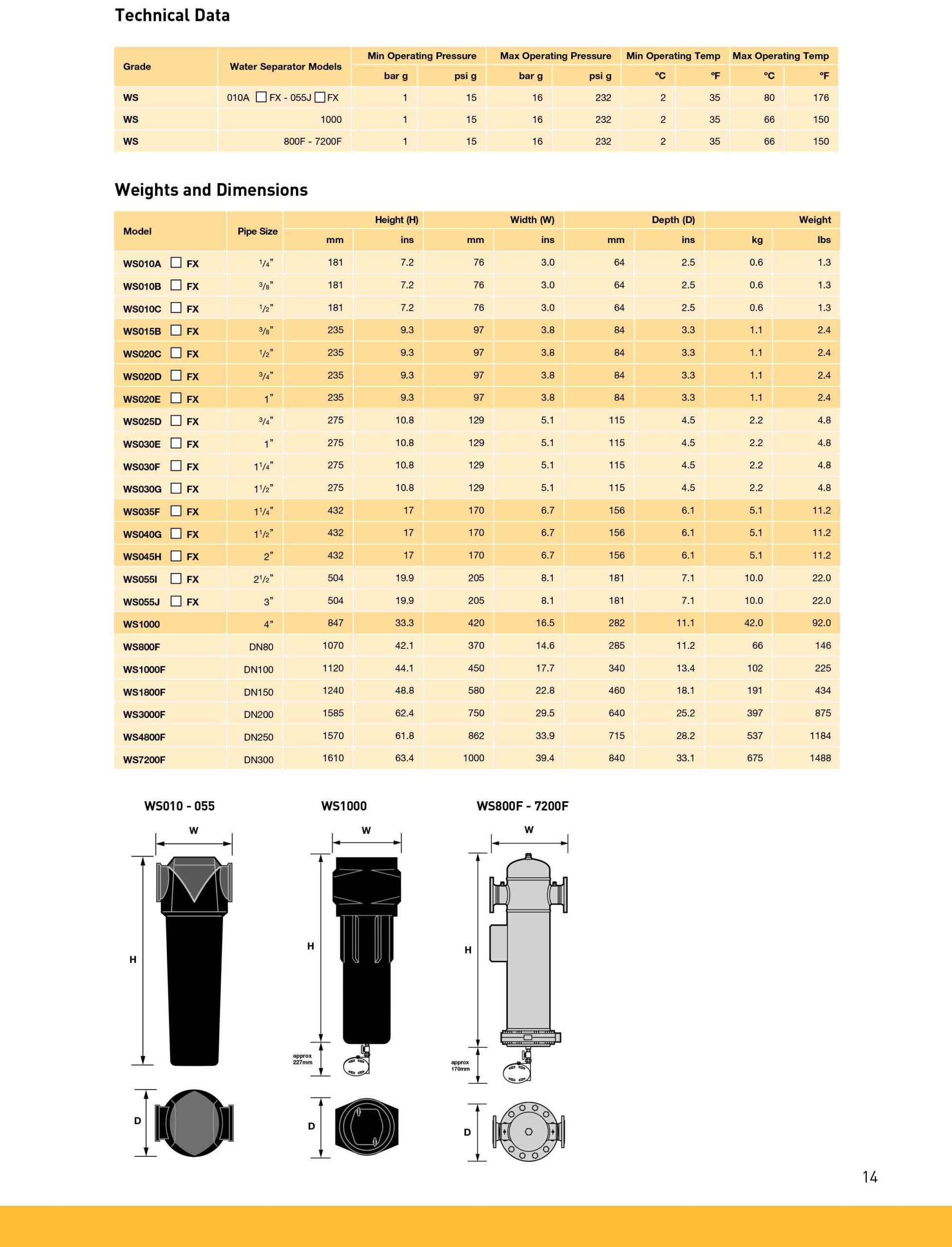

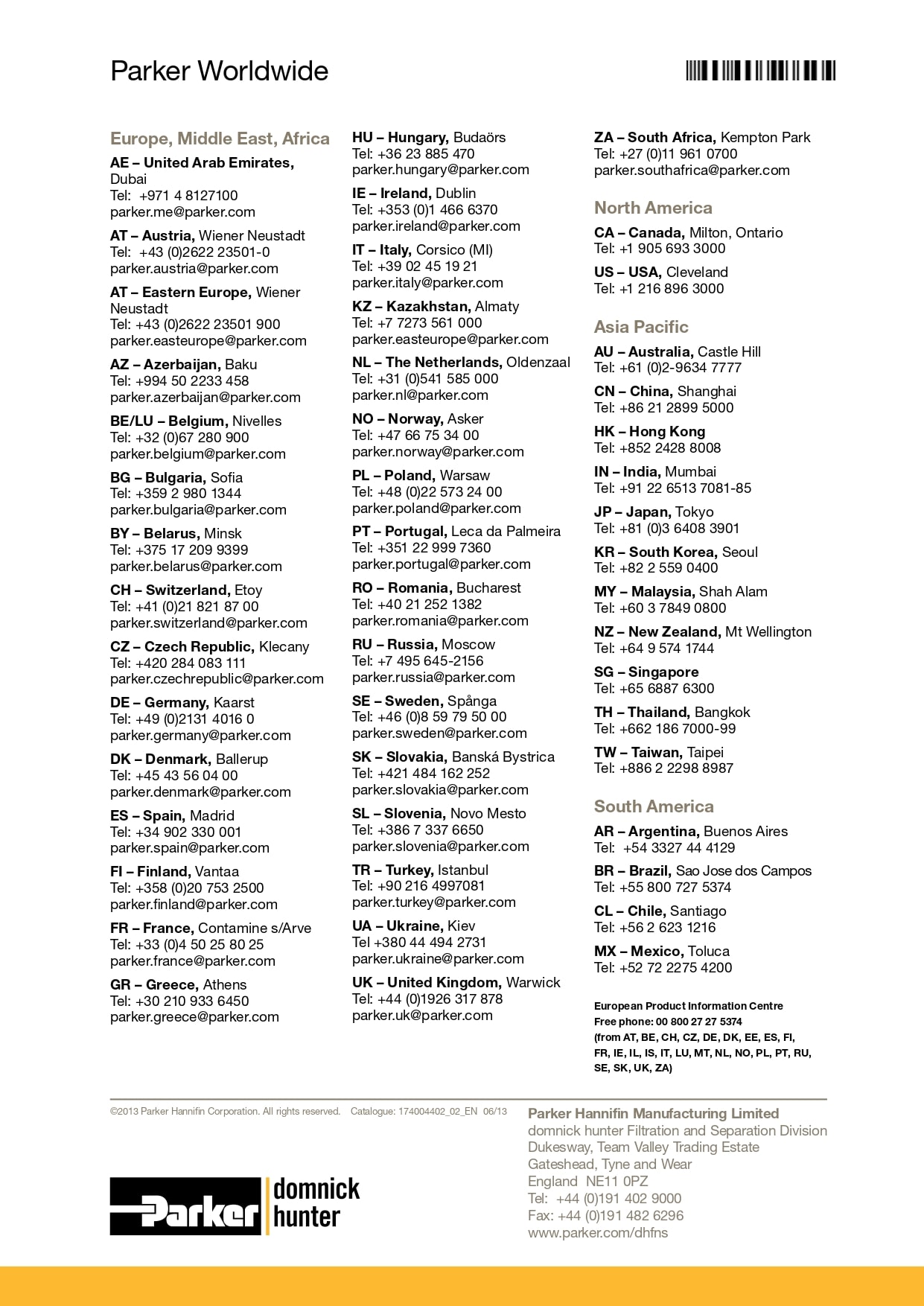

WS Water Separators

OIL-X Evolution filter WS Water Separators utilize centrifugal technology which provides a more efficient method of bulk liquid removal. Using a combination of direction change and centrifugal action, water is effectively separated from the compressed air flow. Parker domnick hunter centrifugal separators which tested in accordance with ISO8573-9 are very efficient with varying flow conditions and have been further optimized to reduce energy costs.

Advanced Filter Housings

OIL-X Evolution filter die-cast housings provide simple installation and long housing life with reduced maintenance. The unique design of the OIL-X Evolution die-cast filter also provides more port sizes to give greater application flexibility. A ‘clean change’ element design ensures that service technicians do not have to directly handle contaminated filter elements during maintenance.

Surgery Room

Surgery Room  Medical Consumables

Medical Consumables  Medical Imaging

Medical Imaging  Cardiovascular

Cardiovascular  Infection Control

Infection Control

phone consultancy

phone consultancy

Download catalog

Download catalog